For inquiries about our products or price list , please leave your email to us and we will be in touch within 24 hour

Overhead OPGW Cable In Transmission Line Aluminum Clad Steel Tube

DOWNLOAD CATEGORY SPECIFICATIONS

Application

Overhead OPGW Cable is suitable for installation on transmission lines and have the dual function of ground wire (designed to replace traditional static or shielding wires) and communication wires.

OPGW conducts short-circuit currents and provides protection against lightning strikes while "shielding" conductors, while providing a telecommunications path for internal and third-party communications.

OPGW must be able to withstand the mechanical and environmental stresses imposed on overhead cables (such as those caused by wind or ice). The OPGW must also be able to handle electrical faults on the transmission line by providing a path to ground while preventing damage to the delicate optical fibers within the cable.

Construction

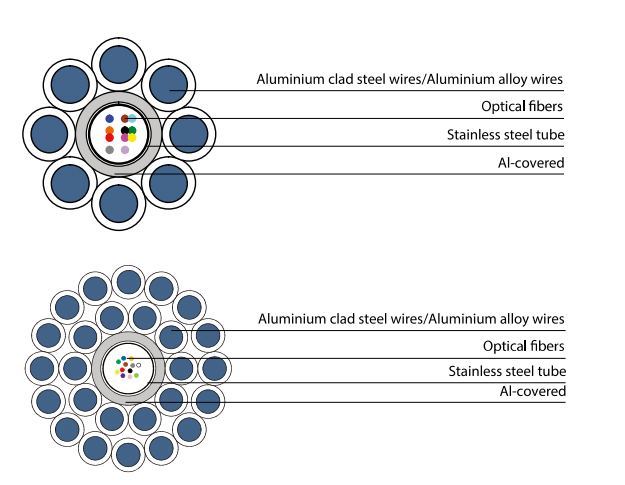

OPGW cable has two constructions:

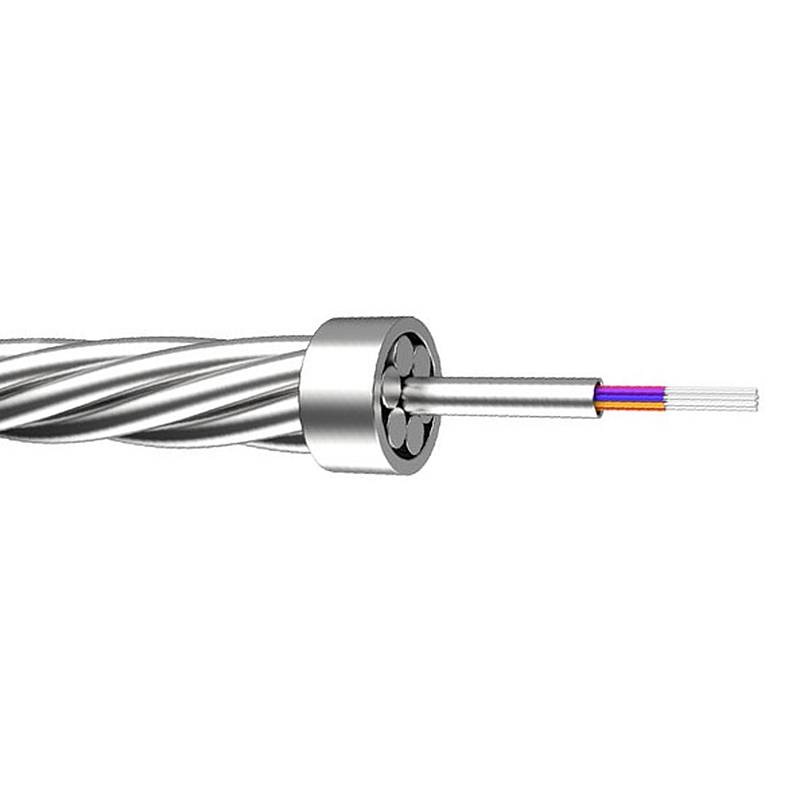

1. Central loose tube type

The fibers are placed loosely in a sealed and water resistant central, aluminum tube filled with water blocking gel. This tube provides protection to the fiber during installation and operation under severe environmental conditions. The stainless steel tube may also be aluminum-clad steel depending on the engineering requirements. The stainless optical tube is located at the center of the cable protected by single or multiple layers of aluminum clad steel, aluminum alloy wires, or steel wires. The metallic wires provide mechanical strength to withstand severe installation and operating conditions, while achieving conductivity to control temperature rise during short circuit conditions.

Each optical fiber is clearly distinguishable utilizing a fiber identification system consisting of coloring and the number of ring marks on it. This compact design features high mechanical strength and fault current rating within a smaller diameter. The smaller diameter also results in excellent sag tension performance.

2.Multi loose tube type

The fibers is placed loosely in a sealed and water resistant stainless steel tube filled with water blocking gel. Two or three stainless steel optical tubes are helically stranded in the inner layer of a multiple-layer cable. The multi loose tube type is designed mostly for very high fiber count requirement over 48 with the maximum fiber count reaching 144. The multi loose tube type can meet the requirement of huge cross and large current capacity.

The optical fiber is made of high pure silica and germanium doped silica. UV curable acrylate material is applied over fiber cladding as optical fiber primary protective coating. The detail data of optical fiber performance are shown in the following table.

Optical fiber uses special spun device successfully controlled the value of PMD, and makes sure that it can keep stable in cabling

Standard

IEC 60793-1 Optical fiber Part 1: Generic specifications

IEC 60793-2 Optical fiber Part 2: Product specifications

ITU-T G.652 Characteristics of a single-mode optical fiber cable

ITU-T G.655 Characteristics of a non-zero dispersion-shifted single-mode optical fiber and Cable

EIA/TIA 598 Color code of fiber optic cables

IEC 60794-4-10 Aerial optical cables along electrical power lines – Family specification for OPGW

IEC 60794-1-2 Optical fiber cables-Part 1-2: Generic specification - Basic optical cable test procedures

IEEE1138-2009 IEEE Standard for testing and performance for optical ground wire (OPGW) for use on electric utility power lines

IEC 61232 Aluminum – clad steel wire for electrical purposes

IEC 60104 Aluminum magnesium-silicon alloy wire for overhead line conductors

IEC 61089 Round wire concentric lay overhead electrical stranded conductors

Fiber is Corning SMF-28e+ Optical Fiber

Options

Hardware for Installation

Notes

Reel lengths must be defined at time of purchase to assist client with reducing waste, and to reduce splicing required during installation.

Please contact AWG for full detailed technical specifications, including PLS CADD data or Stress Creep data.

Send Email to

Us

Send Email to

Us