Bakeng sa lipotso mabapi le lihlahisoa tsa rona kapa lenane la litheko, ka kopo re siele lengolo-tsoibila la hau mme re tla ikopanya le rona nakong ea lihora tse 24.

ABNT NBR 5369 All Aluminium Alloy Steel E Matlafalitsoe

THABELLA LITŠOANTŠISO TSA MOKHATLO

Selelekela

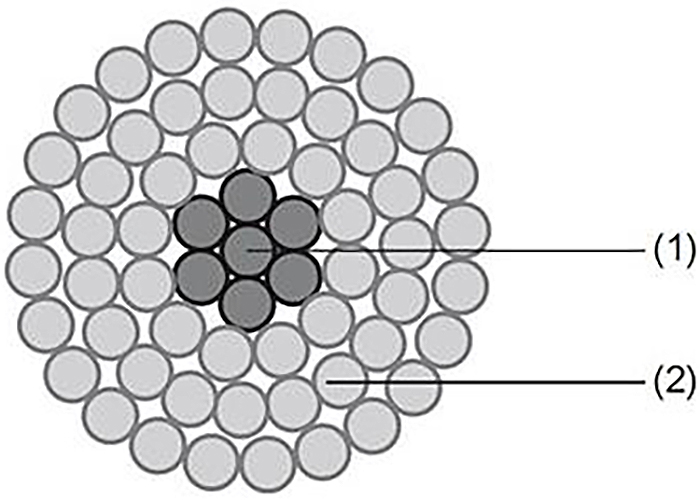

All Aluminium Alloy Steel Reinforced ke sekontiri se tsikinyehileng se entsoeng ka terata e le 'ngoe kapa ho feta ea Aluminium -Magnesium -Silicon Alloy terata e kentsoeng ho pota-pota motheo oa tšepe o nang le matla a phahameng.Mokotla o ka ba oa terata e le 'ngoe kapa terata e mengata e kentsoeng.

AACSR e fumaneha ka tšepe ea mantlha ea Sehlopha sa A, B kapa sa C sa galvanizing kapa Aluminium clad (AW).tšireletso e eketsehileng ea kutu e fumaneha ka ho sebelisoa ha mafura ho ea bohareng kapa ho tšeloa ha mohala o feletseng ka mafura.

Li-conductors li fanoa ka li-reel tsa lehong / tsa tšepe tse sa khutlisetsoeng kapa li-reel tsa tšepe tse Returnable.

Molemo oa AACSR

1. E fana ka matla a nepahetseng bakeng sa moralo oa line.

2. Matla a ntlafetseng ho boima ba 'mele.

3. E loketse bakeng sa nako e telele e eketsehileng ka mojaro o boima.

4. Ho hanyetsa ho hoholo ha kutu.

Kaho

AACSR ke mokhanni ea khoheli ea khoheli e entsoeng ka lera le le leng kapa ho feta tsa 6201 -T81 terata ea aluminium alloy e kentsoeng ka mokokotlo oa tšepe o koahetsoeng ka matla a phahameng.Koko e ka 'na ea e-ba terata e le' ngoe kapa e tsitsitsoe ho itšetlehile ka boholo.

Likarolo tsa motsoako oa aluminium le tšepe li ka fapana ho fumana kamano pakeng tsa matla a hona joale a ho jara le matla a mochini a loketseng ts'ebeliso ka 'ngoe.

Khoele ea mantlha bakeng sa AACSR e fumaneha ka Sehlopha sa A, B kapa sa C-galvanized;"aluminium" (AZ): kapa seaparo sa aluminium (AW).

1. Karolo ea tšepe: Lithapo tsa tšepe tse koahetsoeng ka zinc, terata e le 'ngoe kapa tse ngata tse kentsoeng ka hare.

2. Aluminium alloy: Mehala ea aluminium alloy, concentric stranded

Ho paka

Bolelele ba thomello bo khethoa ho latela lintlha tse kang boholo ba meropa, boima ba meropa, bolelele ba span, thepa ea ho sebetsa kapa kopo ea moreki.

Thepa ea ho Paka

Moropa oa lehong, moropa oa tšepe oa lehong, moropa oa tšepe.

Litlhaloso

ABNT NBR 5369 Standard All Aluminium Alloy Steel E Matlafalitsoe

Romela Imeile ho Rona

Romela Imeile ho Rona