For inquiries about our products or price list , please leave your email to us and we will be in touch within 24 hour

BS EN 50183 AAAC Aluminum Alloy Conductor Cable

DOWNLOAD CATEGORY SPECIFICATIONS

Application

AAAC Aluminum Alloy Conductor Cable is used as bare overhead conductor for primary and secondary distribution. Designed for utilizing a high-strength aluminum-alloy to achieve a high strength-to-weight ratio; affords good sag characteristics.

(1) AAAC conductors are extensively used for overhead distribution and transmission lines adjacent to ocean coastlines where there can be a problem of corrosion in the steel of an ACSR construction.

(2) The Aluminum Alloy Conductor Cable are used in replace of single-layer ACSR conductors to reduce power loss in overhead distribution and transmission lines,when replacing the aluminum conductor steel reinforced , the AAAC can save 5-8% of the construction cost.

(3) AAAC referred to have higher strength but lower conductivity than pure aluminum. Being lighter, alloy conductors can sometimes be used to replace the conventional ACSR.

Advantages

It has the advantage of large transmission amount, good sag performance, low loss, corrosion resistance, simple construction, etc.

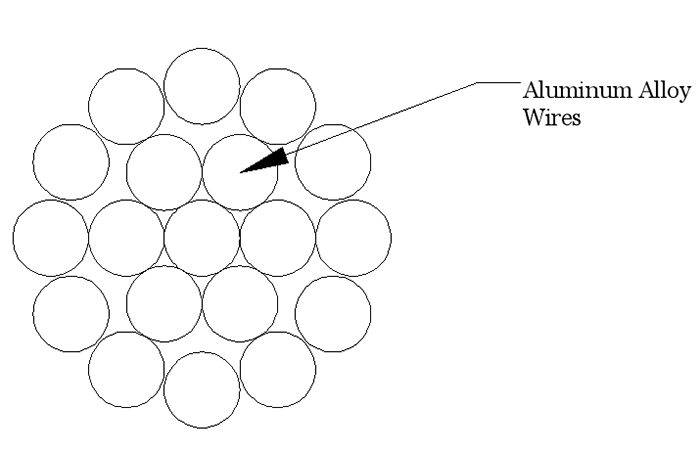

Construction

AAAC is concentric-lay- stranded, similar in construction and appearance with 1350 grade aluminum conductors. They were developed to the need of economical conductor for overhead applications requiring higher strength than that of 1350 grade aluminum conductors, but without a steel core.

Packing

Delivery lengths are determined from a consideration of such factors as physical drum dimensions, drum weights, span length, handling equipment or the customer’s request.

Packing Materials

Wooden drum, steel-wooden drum, steel drum.

Specifications

-BS 3242 Standard Aluminum Alloy Conductors

-BS EN 50183 Standard Aluminum Alloy Conductor Cable.

Send Email to

Us

Send Email to

Us