For inquiries about our products or price list , please leave your email to us and we will be in touch within 24 hour

IEC 61089 Bare AAAC Cable Overhead Transmission & Distribution

DOWNLOAD CATEGORY SPECIFICATIONS

Application

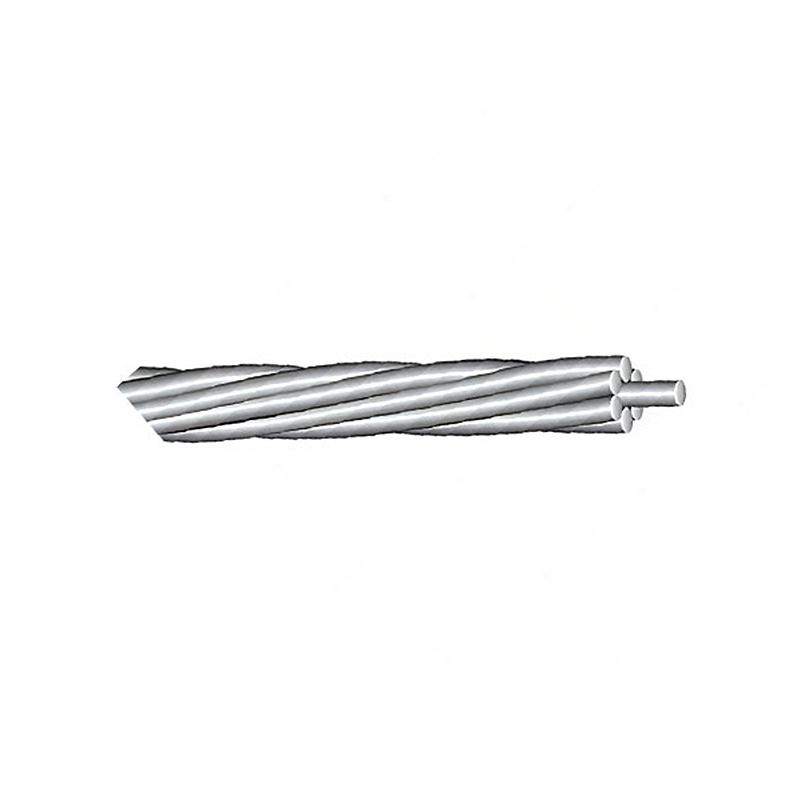

This AAAC Cable is mainly used for overhead power transmission. AAAC can be used in medium and high transmission lines of various voltage levels.Now it has been widely used in power lines across large rivers, heavy ice areas and other special geographical features.

Characteristics

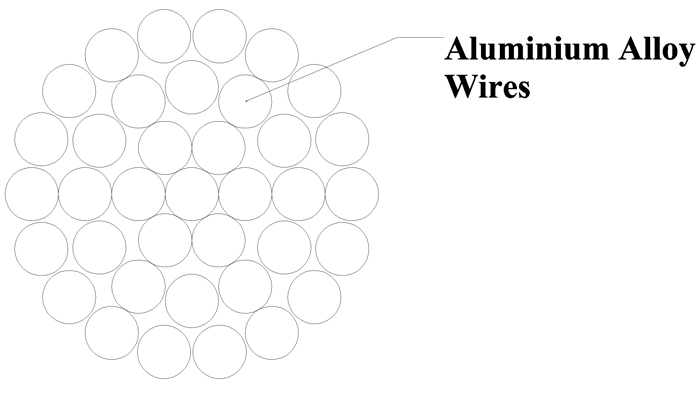

The bare-core stranded AAAC cable is made of heat treated aluminium-magnesium-silicon alloy wires.There are two types of alloy wires designated type A and type B respectively.

Two types of aluminium-magnesium-silicon alloy wires have different mechanical and electrical properties.

- aluminium alloy type B as per IEC 60104, designated A2.

- aluminium alloy type A as per IEC 60104, designated A3.

Construction

Aluminum alloy 6201 wires, concentrically stranded, successive layers having an opposite direction of lay, the outermost layer being right-handed.

Packing

Delivery lengths are determined from a consideration of such factors as physical drum dimensions, drum weights, span length, handling equipment or the customer’s request.

Packing Materials

Wooden drum, steel-wooden drum, steel drum.

Specifications

-IEC 61089 Standard All Aluminum Alloy Conductors

Send Email to

Us

Send Email to

Us