For inquiries about our products or price list , please leave your email to us and we will be in touch within 24 hour

BS 6622 8.7/15kV AWA/SWA XLPE PVC Cable

DOWNLOAD CATEGORY SPECIFICATIONS

Application

AWA/SWA XLPE PVC Cable is an electrical cable that is made up of one or more electrical conductors and is typically sheathed to keep it all together.

Electrical power is transmitted through power cables.

BS 6622 Power cables can be run overhead, buried in the ground, installed as permanent wiring inside of buildings, or left exposed.

Performance

Electrical performance U0/U:

8.7/15 (17.5) kV

Chemical performance :

chemical, UV&oil resistance

Mechanical performance:

Single core - Fixed: 15 x overall diameter

3 core - Fixed: 12 x overall diameter

(Single core 12 x overall diameter and 3 core 10 x overall diameter where bends are

positioned adjacent to a joint or termination provided that the bending is carefully controlled by the use of a former)

Terminal performance:

Fixed: 0°C to +90°C

Fire performance:

- Flame Retardant according to IEC/EN 60332-1-2 Standard

XLPE PVC Cable Constructions

Conductor:

class 2 stranded Cu conductor

Insulation:

Semi-conductive Cross-Linked Polyethylene

Insulation Screen:

Semi-conductive Cross-Linked Polyethylene

Metallic Screen:

Individual or collective overall copper tape screen

Filler:

PET (Polyethylene Terephthalate) fibres

Separator:

Binding tape

Bedding:

PVC (Polyvinyl Chloride)

Armour:

Single core: AWA (Aluminium Wire Armoured)

Multi-core: SWA (Steel Wire Armoured)

Sheath:

PVC (Polyvinyl Chloride)

Sheath Colour:

Red Black

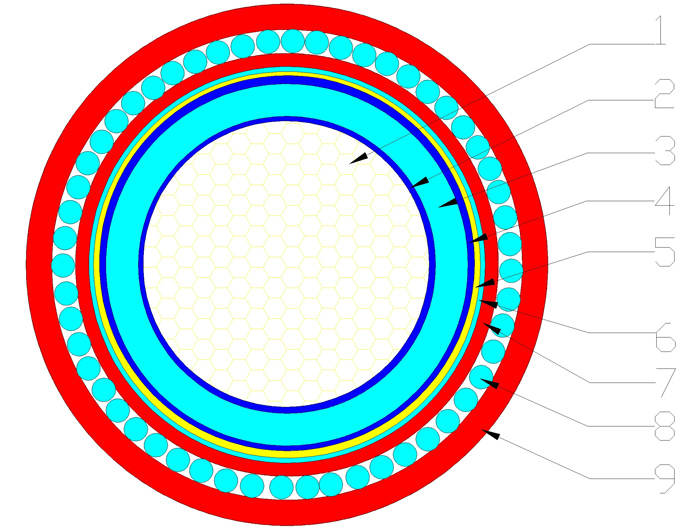

1.Conductor

2.Conductor Screen

3.Insulation

4.Insulation Screen

5.Binding tape

6.Metallic Screen

7.Inner Sheath

8.Armour

9.Outer Sheath

Cable Marking and Packing Materials

Cable Marking:

printing, embossing ,engraving

Packing Materials:

wooden drum, steel drum, steel-wooden drum

Specifications

-BS 6622, IEC/EN 60228 Standard

Send Email to

Us

Send Email to

Us