For inquiries about our products or price list , please leave your email to us and we will be in touch within 24 hour

BS 6622 6.35/11(12)kV Medium Voltage Power Cables

DOWNLOAD CATEGORY SPECIFICATIONS

Application

Medium voltage power cables are suitable for power networks,underground and in cable ducting.They can be buried directly.

Performance

Voltage rating U0/U(Um):

6.35/11(12)kV

Chemical performance:

chemical, UV&oil resistance

Mechanical performance(minimum bending Radius):

-single core unarmoured cable:20 x overall diameter

-single core AWA or aluminum tape armoured cable:15 x overall diameter

- three core unarmoured cable:15 x overall diameter

- three core SWA or STA armoured cable:12 x overall diameter

Thermal performance :

-Maximum operating temperature:90℃

-Maximum short-circuit temperature: 250℃(Max.5s)

-Minimum service temperature:-10℃

Fire performance:

-Flame retardant according to IEC/EN 60332-1-2 standard

-Reduced emission of halogens chlorine <15%

Construction

Conductor:

stranded compacted copper or aluminum conductor , class 2.

Conductor Screen:

Semi-conductive conductor screen.

Insulation:

XLPE (cross-linked polyethylene)

-alternative:EPR (Ethylene Propylene Rubber)

Insulation Screen:

Semi-conductive insulation screen.

Metallic Screen:

individual concentric copper wires and/or copper tape.

Filler:

PET(polyethylene terephthalate) fibres

Binding Tape:

polyester tape or non-woven fabric

Optional Inner Sheath:

PVC(Polyvinyl chloride)

-alternative: LSZH (Low Smoke Zero Halogen)

Optional Armour:

Single-core conductor: AWA (Aluminum Wire Armoring ) or aluminum tape

Three-core conductor: SWA (Steel Wire Armoring ) or galvanized steel tape(single or double layer flat or corrugated)

Outer Sheath:

PVC (polyvinyl chloride)

-alternative :LDPE, MDPE (Low/Medium Density Polyethylene)

-alternative: LSZH (Low Smoke Zero Halogen)

Conductor Shape:

-Single Core:circular, circular compacted

-Three Core:circular, circular compacted, sectorial

Core Identification:

Single Core: Red or black

Three Core: Red , yellow and blue

Sheath Colour:

red, black or other available colour in accord with the request

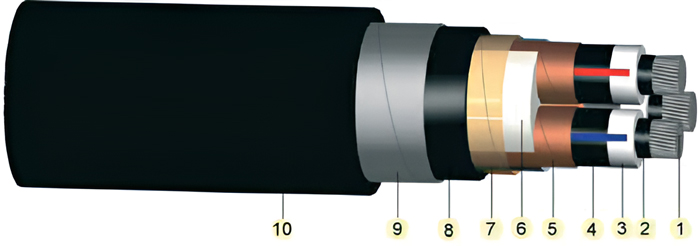

6.35/11(12)kV Three Core Aluminium Conductors XLPE Insulated to BS 6622 Steel Tape Armoured

1.Aluminium Conductor

2.Semi-conductive conductor screen

3.XLPE Insulation

4.Semi-conductive insulation screen

5.Copper tape screen

6.Fillers

7.Tape binder

8.Bedding

9.Galvanised steel tape armour

10.Outer sheath

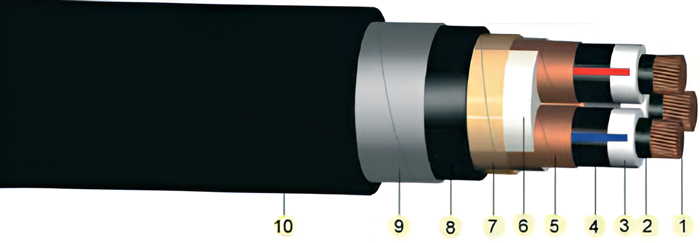

6.35/11(12)kV Three Core Copper Conductors XLPE Insulated to BS 6622 Steel Tape Armoured

1. Copper Conductor

2.Semi-conductive conductor screen

3.XLPE Insulation

4.Semi-conductive insulation screen

5.Copper tape screen

6.Fillers

7.Tape binder

8.Bedding

9.Galvanised steel tape armour

10. Outer sheath

Cable Marking and Packing Materials

Cable Marking:

printing, embossing ,engraving

Packing Materials:

wooden drum, steel drum, steel-wooden drum

Standards

-BS 6622, IEC/EN 60228, IEC 60502-2

Send Email to

Us

Send Email to

Us