For inquiries about our products or price list , please leave your email to us and we will be in touch within 24 hour

AS/NZS 3599-1 MV Aerial Bundle Conductor Cable Overhead Lines

DOWNLOAD CATEGORY SPECIFICATIONS

Application

MV Aerial Bundle Conductor Cable is mainly used for secondary overhead lines on poles or as feeders to residential premises.

Advantage

-Excellent properties against heat aging.

-Resistance to abrasion,moisture and sunlight.

-Good resistance to traction.

-The outer sheath of Bundle Conductor Cable has the following feature:low emission dense smoke and halogen free,flame retardant.

Performance

1. Electrical performance:

6.35/11 KV,12.7/22 KV

2. Chemical performance:

chemical,UV&oil resistance

3. Mechanical performance:

Minimum bending radius:10 x cable diameter

4. Terminal performance:

Maximum service temperature: 90℃

Maximum short-circuit temperature: 250℃(Max.5s)

Minimum service temperature: -40℃

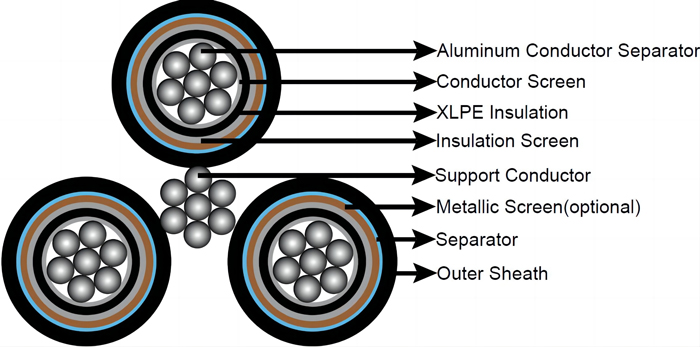

Construction

Phase Conductor:

Circular compacted stranded H68 aluminium to BS2627.

Phase Core Identification:

colour strip, rib or number

Conductor Screen:

Extruded semi-conductive layer.

Insulation:

XLPE.

Insulation Screen:

Extruded semi-conductive layer.

Metallic Screen(optional):

Copper wire screen or copper tape screen.

Separator:

Semi-conductive swellable tape.

Outer Sheath:

HDPE.

Support Conductor:

Galvanized steel wires.

Assembly:

Three XLPE insulated screened cores are bundled around the galvanized steel wires in a right hand lay.

Cable Marking and Packing Method

Cable Marking:

printing, embossing, engraving

Packing Materials:

wooden drum, steel drum, steel-wooden drum

Send Email to

Us

Send Email to

Us