Rau kev nug txog peb cov khoom lossis daim ntawv teev nqi, thov tso koj tus email rau peb thiab peb yuav teb rau hauv 24 teev

BS EN 50525 Flexible PVC SY Control Cable Hlau Hlau Braid

DOWNLOAD CATEGORY SPECIFICATIONS

Cov ntsiab lus ceev

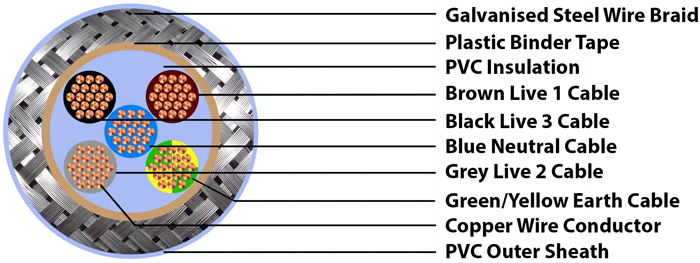

Hlau braided multicore PVC SY Control Cable rau kev tiv thaiv kev tiv thaiv ntxiv.Muaj nyob rau hauv Number coded los yog Colour Coded core identification.Plain Annealed Flexible Copper Conductors / PVC Insulated / PVC Bedding / GSWB (Galvanised Steel Wire Braid) / PVC Sheathed.300/500V

Daim ntawv thov

SY cable yog tsim los siv los ua kev sib txuas cable rau kev ntsuas, tswj lossis kev tswj hwm hauv cov cuab yeej tswj kev sib dhos thiab cov kab ntau lawm, conveyors thiab rau computer units.Nws yog feem ntau siv nyob rau hauv ntau qhov kev lag luam suav nrog kev tsim vaj tsev thiab kev tsim kho, kev tsheb nqaj hlau thiab kev thauj mus los, kev sib kis thiab automation thiab kev tswj cov txheej txheem.

Cov cable no kuj tseem siv los ntawm cov kws tshaj lij hluav taws xob hauv qee qhov kev teeb tsa ruaj khov uas tsuas yog lub teeb pom kev zoo yuav tshwm sim.Cov kab no kuj tuaj yeem siv sab nraum zoov (tab sis yuav tsum tau tiv thaiv);Txawm li cas los xij, nws yog qhov zoo tshaj plaws rau qhov chaw qhuav lossis ntub dej hauv tsev.

Raws li lub zog thiab txuas cable hauv cov nroj tsuag engineering thiab kev tsim kho, kev siv tshuab thiab hauv cua sov thiab cua txias tshuab raws li

zoo li nyob rau hauv cov cheeb tsam uas muaj siab mechanical stress.

Kev ua tau zoo

Cov khoom hluav taws xob ntawm 20 ° C

Nominal voltage: U₀ / U: 300 / 500 V

Test voltage:

tub ntxhais / tub ntxhais: 4000V AC

core / npo: 4000V AC

Mechanical thiab thermal zog

Yam tsawg kawg bending radius:

Qee zaus flexing: 20 x cable txoj kab uas hla

taag installation: 6 x cable txoj kab uas hla

Qhov kub thiab txias:

Qee zaus flexing: -5˚C txog +70˚C max.conductor temp.

Kev txhim kho ruaj khov: -40˚C txog +80˚C max.conductor temp.

Flammability: acc.Raws li IEC 60332-1-2

Kev tsim kho

Tus neeg xyuas pib:

Plain Annealed Copper Class 5 rau BS EN 60228

Rwb thaiv tsev:

PVC Hom TI2 rau BS EN 50363-3

Lub txaj:

PVC Hom TM2 rau BS EN 50363-4-1

Braiding:

GSWB (Galvanized Steel Wire Braid)

Sheathing:

PVC Hom TM2 rau BS EN 50363-4-1

Cable Marking thiab Packing Materials

Cable Marking:

luam ntawv, embossing, engraving

Cov khoom ntim:

ntoo nruas, steel nruas, steel-ntoo nruas

Txuj

BS EN 50525-2-11: 2011 Txuj

Xa Email rau peb

Xa Email rau peb