For inquiries about our products or price list , please leave your email to us and we will be in touch within 24 hour

AEIC CS8-07 25kV Copper Aluminum MV 105 Wire 3 Conductor

DOWNLOAD CATEGORY SPECIFICATIONS

Application

Within the power system, Copper Aluminum MV 105 Wire is utilized to deliver and move electrical energy.Between the national high-voltage network and the residential, commercial, and industrial structures, which serve as the final recipients of power, MV-105 wires are utilized in the preliminary stage.

Construction

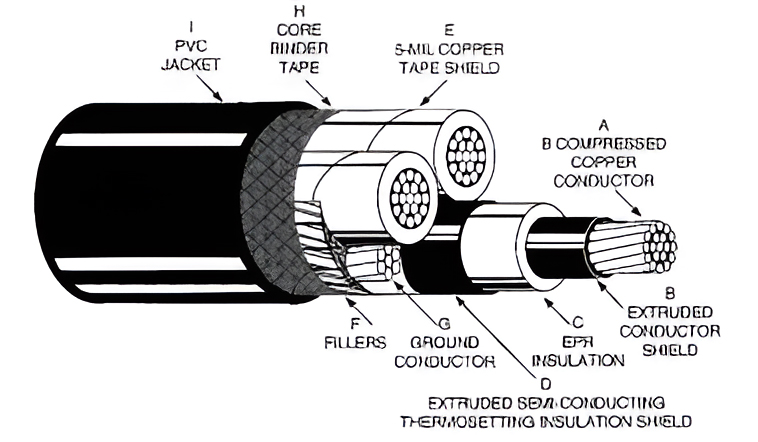

Conductor:

Compressed concentric strand or soft drawn annealed copper in Class B in accordance with ASTM B3.

According to ASTM B 231, Class A or B compressed concentric stranded aluminum alloy 1350. With conductor filling compound, stranded conductors are water-blocked.

Conductor Shield:

Extruded thermosetting semiconducting shield which is free stripping from the conductor and bonded to the insulation

Insulation:

EPR insulation

Insulation Shield:

Extruded thermosetting semiconducting shield with controlled adhesion to the insulation providing the required balance between electrical integrity and ease of stripping.

Metallic Shield:

The metallic shield is flat uncoated 5-mil thick copper tape helically applied with minimum 20% overlap. A Mylar ribbon is longitudinally applied under the copper tape shield for phase identification - 1C w/Red, 1C w/Blue, and 1C w/None.

Grounding Conductors:

Three bare stranded copper conductor, one in each interstice.

Fillers:

Non hygroscopic fillers, forming a firm and cylindrical cable core.

Binder Tape:

A binder tape is applied to maintain core symmetry and mechanical stability.

Jacket:

Black, sunlight resistant, flame retardant PVC jacket tightly applied over the binder tape.

Cable Marking and Packing Materials

Cable Marking:

printing, embossing ,engraving

Packing Materials:

wooden drum, steel drum, steel-wooden drum

Standards

AEIC CS8, Specifications for Shielded Power Cable, 5-46kV

ICEA S-93-639, 5-46 kV Shielded Power Cable

ICEA S-97-682, Utility Shielded Power Cable Rated 5-46 kV

UL 1072 MV-105

IEEE- IEEE 383 Flame Test

For 105°C continuous, 140°C emergency, 250°C short-circuit operation.

CSA Standard C68.5-07 File # 257759 Primary Shielded and Concentric Neutral Cable for Distribution

Send Email to

Us

Send Email to

Us